CERAMCAST foundry sand is one kind of special ceramic sand, which with the low thermal expansion coefficient. Using CERAMCAST foundry sand, the moulds and cores, the veins and other expansion defects of castings are eliminated

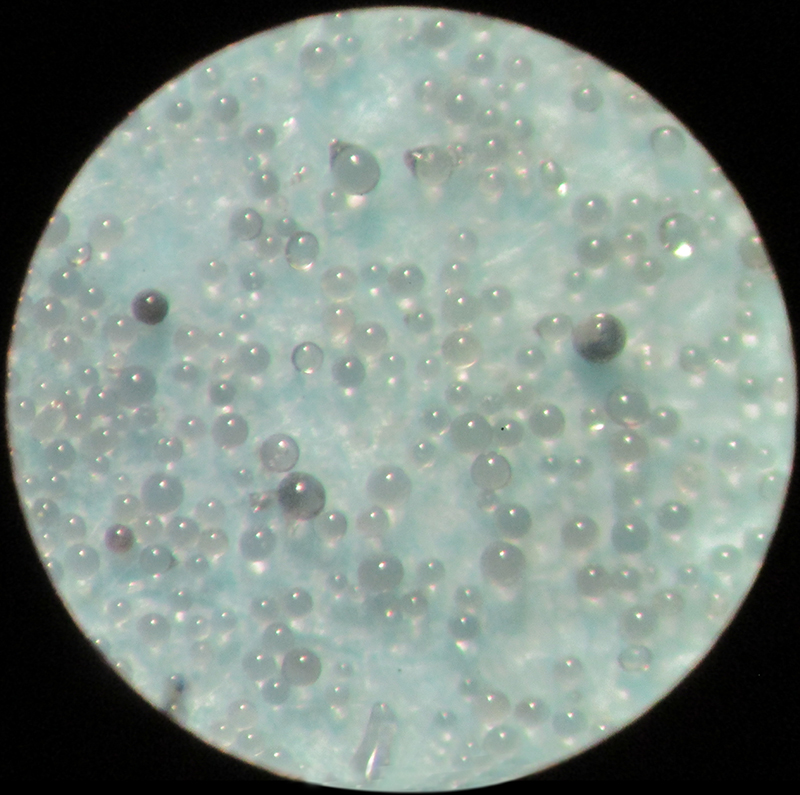

Great spherical shape of the particle, excellent flowability and easy to fill in. The moulds and cores are with high permeability and easily shakeout after casting

We can save 30-50% of the binder consumption with the smooth surface and substantial structure.

CERAMCAST foundry sand is a neutral and inert material (Al2O3 > 70%), suitable in acid and alkali binders systems, also suitable for various alloys.

High refractoriness (over 1850℃)and good stability. It is especially suitable for the production of complexity sand cores and steel castings.

We can provide the particle size as per customer requirements from 12 Mesh to 270 Mesh.

Excellent hardness and refractoryness, our CERAMCAST foundry sand can be recycle collected and used for long term working life.